2025 Guide: How to Choose the Best Micro Injection Molding Machine

In the rapidly advancing field of manufacturing, the micro injection molding machine has emerged as a pivotal tool for producing intricate and precise components across various industries. As the demand for miniaturized parts continues to rise—especially in sectors such as electronics, automotive, and medical devices—the need for a reliable and efficient micro injection molding machine becomes paramount. This guide aims to provide prospective buyers with essential insights to navigate the complexities of selecting the most suitable machine for their specific needs.

Choosing the right micro injection molding machine involves understanding various factors, including machine specifications, operational capabilities, and the intricacies of the molding process itself. Whether you are a seasoned manufacturer or a newcomer to the industry, this guide will help you identify key considerations that contribute to optimal performance and product quality. By focusing on critical attributes such as precision, speed, and versatility, you can make an informed decision that enhances your production efficiency and meets the growing demands of the market.

Understanding Micro Injection Molding and Its Applications

Micro injection molding is an essential manufacturing process designed for creating intricate and precise components used in various applications, including medical devices, electronics, and automotive parts. This technique is particularly beneficial due to its ability to produce small to micro-sized parts with complex geometries, improving production efficiency and reducing material waste. According to a recent industry report, the micro injection molding market is anticipated to reach USD 1.2 billion by 2025, growing at a CAGR of 6.7%. This growth is driven by the increasing demand for miniaturized components in high-tech applications.

When choosing a micro injection molding machine, understanding the applications of micro injection molding can greatly influence your decision. This process is critical for industries that require high precision and repeatability, such as healthcare and electronics. The ability to mold complex shapes with tight tolerances makes it ideal for producing components like housings for sensors or intricate parts for surgical instruments. Furthermore, advancements in materials, such as bio-compatible resins, enhance the process's applicability, particularly in the medical field.

**Tips:** When selecting a micro injection molding machine, consider the machine's clamping force and injection volume, as these factors can significantly affect the quality of the molded parts. Understand the output capabilities and ensure the machine can handle the specific material types required for your applications. Regular maintenance and operator training are also crucial to maximizing the efficiency and longevity of the machinery.

Key Features to Consider in a Micro Injection Molding Machine

When selecting a micro injection molding machine, it's essential to focus on key features that can significantly impact your production efficiency and product quality. One critical feature to consider is the machine's precision. Look for machines that offer high accuracy in injection volume and positioning, as even minor deviations can lead to significant defects in micro-sized components. Additionally, a machine that operates with advanced control systems will enhance the stability and consistency of the injection process.

Another important aspect is the clamp force. The clamp force must be adequate to securely hold the mold during the injection cycle, particularly when dealing with delicate micro parts that are prone to warping. Choosing a machine with adjustable clamp pressure can provide flexibility for various production demands. Furthermore, consider the machine's cycle time; a machine designed for faster cycles can increase productivity and reduce overall manufacturing costs.

Tips: When assessing micro injection molding machines, it's wise to conduct a thorough analysis of your specific production needs. This can involve prototyping with different machines to gauge their performance before making a final decision. Also, investing in a machine with a robust after-sales support system can save you time and ensure less downtime in the long run. Remember, the right machine is crucial to achieving high-quality results in micro injection molding.

2025 Guide: How to Choose the Best Micro Injection Molding Machine - Key Features to Consider

| Feature | Description | Importance |

|---|---|---|

| Clamping Force | The clamping force determines the machine's ability to hold the mold closed during injection, crucial for preventing defects. | High importance |

| Injection Speed | Faster injection speeds can improve cycle times and reduce the risk of short shots. | Medium importance |

| Injection Pressure | Higher injection pressure allows for better material flow and filling of complex molds. | High importance |

| Temperature Control | Maintaining optimal temperatures is vital for consistent material properties and part quality. | High importance |

| Mold Size Compatibility | Ensure the machine can accommodate the size and complexity of your molds for effective production. | Medium importance |

| Energy Efficiency | Energy-efficient machines lower operating costs and can lead to a smaller carbon footprint. | Medium importance |

| Ease of Use | User-friendly interfaces and controls can drastically reduce setup time and operator training needs. | Medium importance |

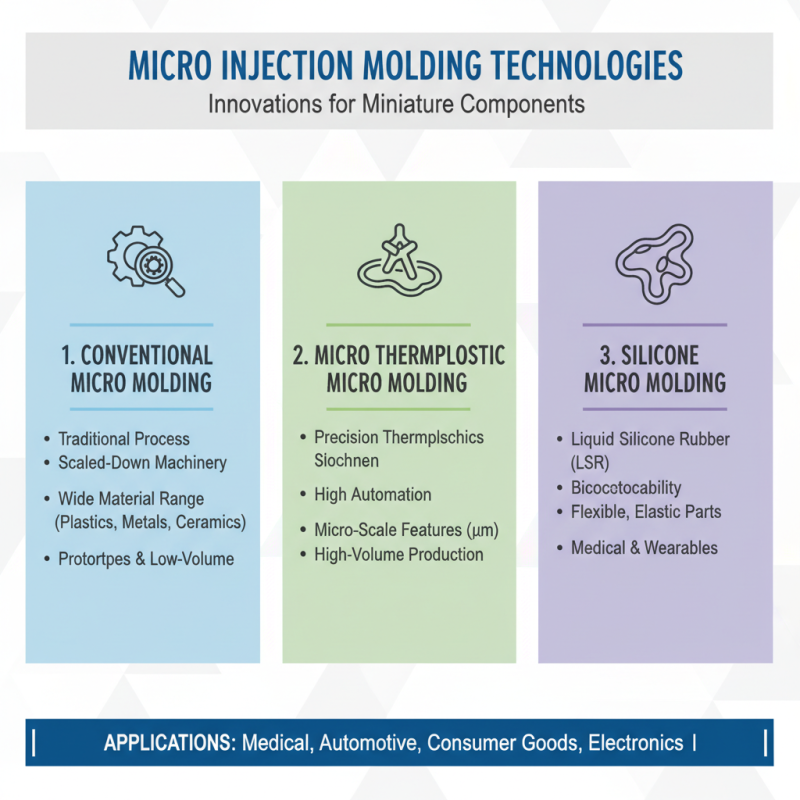

Comparing Different Types of Micro Injection Molding Technologies

Micro injection molding technologies have evolved significantly, allowing for the production of intricate components in various industries such as medical, automotive, and consumer goods. The three primary types of micro injection molding technologies include conventional micro molding, micro thermoplastic molding, and silicone micro molding. Each method has unique advantages and applications, making it essential to understand their differences when selecting a suitable machine.

Conventional micro molding utilizes traditional thermoplastic materials and is ideal for producing small, precise components. According to a report from Research And Markets, the conventional micro molding market is projected to grow at a CAGR of over 12% between 2022 and 2027, driven by increasing demand for high-precision components in the medical device sector. On the other hand, micro thermoplastic molding introduces high-pressure injection of small thermoplastic pellets to create high-quality parts with intricate designs, making it particularly beneficial for complex geometries. This method has seen a rise in popularity, accounting for approximately 25% of the micro molding market in recent years.

Silicone micro molding, an emerging technology, offers advantages in terms of flexibility and biocompatibility, making it a preferred choice for medical applications such as drug delivery systems and implants. The global silicone injection molding market is expected to reach USD 7.3 billion by 2027, according to a recent industry analysis. By comparing these technologies, manufacturers can make informed decisions based on their specific needs, ultimately choosing a machine that optimally balances efficiency, cost, and product quality.

Evaluating Cost, Maintenance, and Support for Molding Machines

When considering the purchase of a micro injection molding machine, evaluating cost, maintenance, and support is crucial for making an informed decision. The initial price of a machine can vary widely based on its features and specifications. Keep in mind that the lowest price may not always translate to the best value; it’s important to assess the total cost of ownership, including energy consumption, operational efficiency, and potential downtime.

Maintenance practices significantly impact the longevity and performance of molding machines. Opt for models with easy access to critical components, which simplifies routine maintenance tasks. Implementing a preventive maintenance schedule can reduce unexpected repairs and prolong the machine’s lifespan. Operators should also be trained adequately to perform basic maintenance checks, ensuring that the machine runs smoothly and efficiently.

Tips: Always inquire about the availability of spare parts and the response time for service support from the manufacturer. Additionally, consider machines that come with comprehensive user manuals and online resources to assist with troubleshooting and maintenance routines. Staying proactive in maintenance and support will not only enhance production quality but also ultimately save costs in the long run.

Future Trends in Micro Injection Molding and Machine Selection

The landscape of micro injection molding is evolving rapidly, driven by advancements in materials and technology. As the industry moves towards greater precision and efficiency, understanding future trends becomes crucial for selecting the optimal micro injection molding machine. Emerging materials, such as bio-based and biodegradable plastics, are gaining traction, prompting manufacturers to seek machines that can handle a wider range of materials while maintaining high-quality output. Machines equipped with advanced temperature control systems and automation features are increasingly favored, as they ensure consistency and reduce production times.

Additionally, the incorporation of Industry 4.0 principles is becoming more prevalent in micro injection molding. Smart machines that utilize IoT connectivity are able to gather and analyze data in real-time, allowing for predictive maintenance and improved operational efficiency. This shift towards automation and data-driven decision-making will not only enhance production capabilities but also provide manufacturers with detailed insights into their processes. Thus, when choosing a micro injection molding machine, companies should prioritize features that support adaptability and integration with smart technologies, ensuring they remain competitive in an ever-evolving market.

Related Posts

-

Exploring the Diverse Types of Injection Molding Machines for Your Manufacturing Needs

-

Comparing Efficiency and Cost: Mini Plastic Injection Molding Machines Vs. Traditional Methods

-

Maximizing Production Efficiency with Advanced Plastic Molding Machines

-

Why Electric Injection Molding Machines Are Revolutionizing Manufacturing Efficiency

-

Unlocking Efficiency: The Future of Small Plastic Molding Machines in Sustainable Manufacturing

-

Global Quality Revolution How Chinese Moulding Plastic Machines Capture International Markets