Top Benefits of Electric Injection Molding Machines for Your Manufacturing Needs

In today’s rapidly evolving manufacturing landscape, businesses are increasingly turning to advanced technologies to enhance efficiency and sustainability. Among these innovations, the electric injection molding machine stands out as a transformative solution that offers significant benefits over traditional hydraulic systems. Industry expert Dr. Martin Lewis, a leading authority in plastic manufacturing technology, asserts, "The shift towards electric injection molding machines not only reduces energy consumption but also improves precision, making it a game-changer for manufacturers striving for excellence."

The adoption of electric injection molding machines is fueled by their remarkable advantages, including lower operational costs, reduced carbon footprint, and enhanced production speed. As companies aim to meet growing consumer demands while adhering to stringent environmental regulations, these machines provide the perfect balance between performance and sustainability. With a focus on minimizing waste and maximizing output, electric injection molding machines are becoming essential tools for modern manufacturing operations.

Furthermore, the precision and consistency offered by electric systems empower manufacturers to produce high-quality parts with minimal variation. As Dr. Lewis aptly notes, "Precision in manufacturing is key to maintaining competitive advantage, and electric injection molding machines deliver that with unparalleled accuracy." As manufacturers evaluate their production strategies, the integration of electric injection molding technology is poised to be a pivotal factor in achieving long-term success and resource efficiency.

Advantages of Electric Injection Molding Machines in Manufacturing

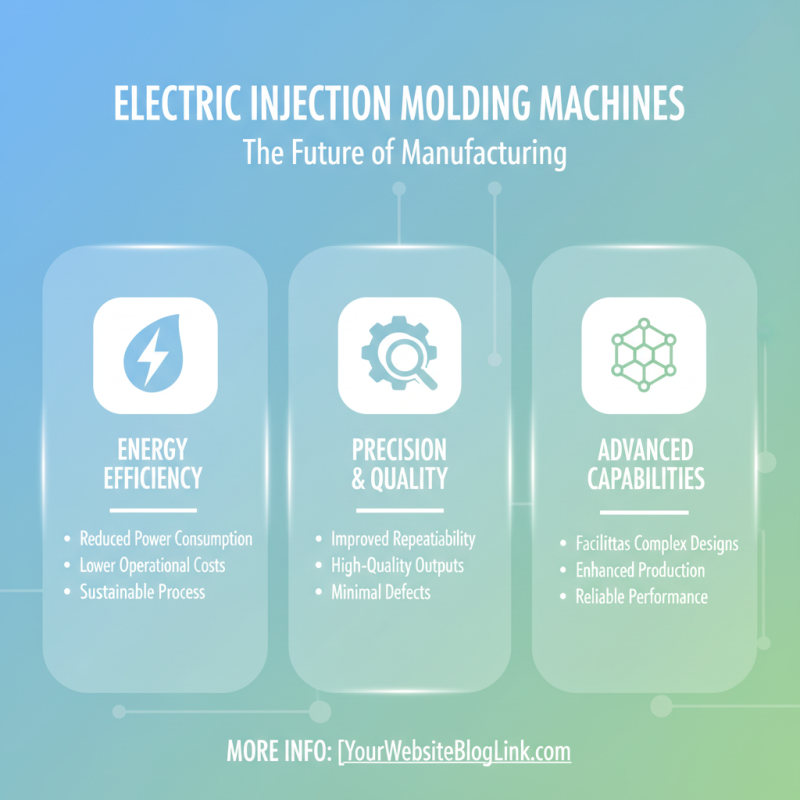

Electric injection molding machines are increasingly becoming the preferred choice for manufacturers due to their numerous advantages that enhance production efficiency and reliability. One significant benefit is energy efficiency; these machines consume less power compared to traditional hydraulic systems. This not only reduces operational costs but also promotes a more sustainable manufacturing process. Additionally, electric machines offer improved precision and repeatability, which ensures high-quality outputs with minimal defects. This precision also facilitates complex designs that might be challenging to achieve with conventional methods.

When considering the switch to electric injection molding machines, it’s essential to evaluate your specific manufacturing needs. **Tip**: Conduct a cost-benefit analysis to determine the long-term financial impact of upgrading your equipment. This includes an assessment of energy savings, maintenance costs, and the potential for increased production rates.

Moreover, the quieter operation of electric injection molding machines creates a more pleasant working environment for operators, minimizing noise-related fatigue. **Tip**: Invest in training for your team to maximize the advantages of these machines, focusing on their control systems and maintenance practices. Understanding the technology fully can lead to enhanced output and reliability in your production process.

Energy Efficiency and Cost Savings of Electric Machines

Electric injection molding machines are revolutionizing manufacturing processes, particularly through their energy efficiency and cost savings. Unlike traditional hydraulic machines, electric machines utilize servo motors to drive the injection process, which significantly reduces energy consumption. Research shows that electric models can use up to 50% less energy compared to their hydraulic counterparts. This reduction not only benefits the environment but also translates into lower operational costs, making it an attractive option for manufacturers looking to improve their bottom line.

Tips for maximizing energy efficiency include regularly maintaining the machine to ensure optimal performance and programming energy-saving modes during downtime. Additionally, considering the purchase of machines with advanced features, such as variable speed drives, can further enhance efficiency. Investing in energy-efficient technologies may come with higher upfront costs, but the long-term savings in energy bills make it a wise decision. Furthermore, applying careful material handling procedures can minimize waste, adding to the overall cost savings.

Utilizing electric injection molding machines also allows for greater precision in production, which can reduce scrap rates and lead to fewer reworks. This not only contributes to material savings but also enhances product quality, further benefiting your manufacturing operations. Adopting these practices positions manufacturers to thrive in a competitive market, while simultaneously supporting sustainability efforts.

Top Benefits of Electric Injection Molding Machines

Precision and Consistency in Production Processes

Electric injection molding machines have revolutionized the manufacturing industry by providing unmatched precision and consistency in production processes. Unlike traditional hydraulic machines, electric counterparts rely on servo motors to control every aspect of the injection process. This results in a higher degree of accuracy in material placement and mold filling, ensuring that each piece produced meets exact specifications. The precision offered by electric machines minimizes the variation in the final product, which is crucial for industries demanding high-quality components, such as automotive, medical, and consumer electronics.

Moreover, the consistency achieved through electric injection molding enhances overall operational efficiency. With the ability to maintain stable temperature and pressure conditions throughout the injection cycle, these machines significantly reduce the likelihood of defects caused by fluctuations. As a result, manufacturers can achieve uniform production runs, reducing waste and lowering costs associated with rework. The capability to execute intricate designs with exact tolerances further solidifies the role of electric injection molding machines as a cornerstone of modern manufacturing, enabling businesses to meet both quality demands and production deadlines effectively.

Environmental Impact Reduction through Electric Injection Molding

Electric injection molding machines are increasingly recognized for their critical role in reducing environmental impacts within the manufacturing sector. Unlike traditional hydraulic machines that consume significant amounts of energy and often rely on oil-based systems, electric machines utilize servo motors to optimize energy use. This technology not only lowers energy consumption during production but also enhances precision, resulting in reduced material waste and a smaller environmental footprint.

Moreover, electric injection molding machines contribute to a cleaner manufacturing process by minimizing emissions. With their ability to operate at lower temperatures and achieve more consistent results, these machines limit the release of harmful gases and pollutants into the atmosphere. The reduced use of hydraulic fluids also mitigates the risk of spills and leaks, promoting safer working environments and enhancing overall site cleanliness. As industries globally strive to meet stricter environmental regulations, transitioning to electric injection molding technology represents a significant step toward sustainable manufacturing practices.

Flexibility and Versatility in Design Applications

Electric injection molding machines are increasingly becoming essential in modern manufacturing due to their unmatched flexibility and versatility in design applications. As reported by industry analysts, machinery equipped with electric drive systems can achieve precision levels of up to 0.01 mm, significantly enhancing product quality while reducing waste. This precision allows manufacturers to handle a wider range of materials and complex geometries, making it easier to innovate and adapt to changing market demands.

Moreover, electric machines cater to various industries from automotive to consumer electronics by enabling rapid prototyping and short-run production. Research indicates that these machines can enhance cycle times by up to 30% compared to traditional hydraulic counterparts, facilitating faster time-to-market for new products. The ease of adjusting parameters and quick changeover capabilities empower manufacturers to pivot rapidly, producing diverse parts without extensive downtime or setup costs. Such versatility not only optimizes efficiency but also creates a sustainable manufacturing environment, as energy consumption is markedly lower with electric systems—often reducing energy usage by 30-50%, according to recent studies conducted by industry experts.

Top Benefits of Electric Injection Molding Machines for Your Manufacturing Needs

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Energy Efficiency | Electric machines consume less energy compared to hydraulic machines. | Reduced operational costs and lower carbon footprint. |

| Precision Control | Highly accurate and repeatable processes, leading to better part consistency. | Improved product quality and reduced scrap rates. |

| Reduced Noise Levels | Electric injection molding machines operate more quietly than hydraulic systems. | Better working environment and compliance with noise regulations. |

| Compact Design | Smaller footprint makes them suitable for environments with limited space. | More efficient use of factory floor space. |

| Flexibility in Material Use | Compatible with a wide range of materials and resins. | Ability to easily switch between different materials for diverse product lines. |

Related Posts

-

Evaluating the Best Large Injection Molding Machines for Global Buyers in 2025 Industry Trends and Insights

-

7 Best Small Plastic Injection Machines for Efficient Production in 2023

-

How to Choose the Right Type of Injection Molding Machine for Your Business

-

How to Optimize Production Efficiency with Small Injection Molding Machines in Your Manufacturing Process

-

How to Choose the Best Home Plastic Injection Molding Machine for Your DIY Projects

-

How to Enhance Production Efficiency with Plastic Injection Machines for Optimal ROI