Essential Tips for Using Large Injection Molding Machines?

Using a large injection molding machine can be quite challenging. These machines play a significant role in manufacturing various products. Understanding their operation is essential for achieving high-quality outputs.

When working with a large injection molding machine, precision matters. Small adjustments can lead to substantial differences in the end product. Operating such machines may seem straightforward, yet many users overlook critical details, causing frustration.

Common errors include improper temperature settings and insufficient mold maintenance. It's crucial to regularly inspect and clean molds. Additionally, familiarizing yourself with the machine’s manual can prevent costly mistakes. Remember, even experienced operators can benefit from revisiting the basics. Embracing a learning mindset can enhance efficiency and output quality.

Understanding the Basics of Large Injection Molding Machines

Large injection molding machines play a crucial role in manufacturing industries. Understanding their workings can enhance productivity. These machines are designed to create large plastic parts. They operate by injecting molten plastic into a mold. This process requires precise temperature control and timing.

Operators must monitor the machine closely. An incorrect setting can lead to defects. Quality checks during production are vital. Small mistakes can result in significant losses. Companies should invest in training workers. Knowledgeable staff can prevent costly errors.

Furthermore, machine maintenance is often overlooked. Regular checks for wear and tear are essential. Neglecting this can lead to downtime. Employees should track machine performance metrics. This data helps identify patterns and potential issues. Continuous improvement is key in utilizing large machines effectively.

Key Specifications and Features of Large Injection Molding Machines

Large injection molding machines play a crucial role in producing large plastic parts. These machines often have impressive specifications that set them apart. Pay close attention to clamping force, injection weight, and shot size. These factors determine the machine's capability and efficiency.

A key feature to consider is the machine's stability during operation. Vibrations can lead to defects in the final product. Regular maintenance checks can help ensure the machine operates smoothly. Additionally, look for machines with advanced control systems. These systems improve precision and reduce waste.

When using large injection molding machines, be mindful of the energy consumption. It’s important to assess the operational costs. Consider switching to energy-efficient models where possible. Placing the machines in optimal locations can also help minimize energy use. Keep all these factors in mind while operating large injection molding machines for the best results.

Essential Tips for Using Large Injection Molding Machines

Tips for Efficient Setup and Operation of Large Injection Molding Machines

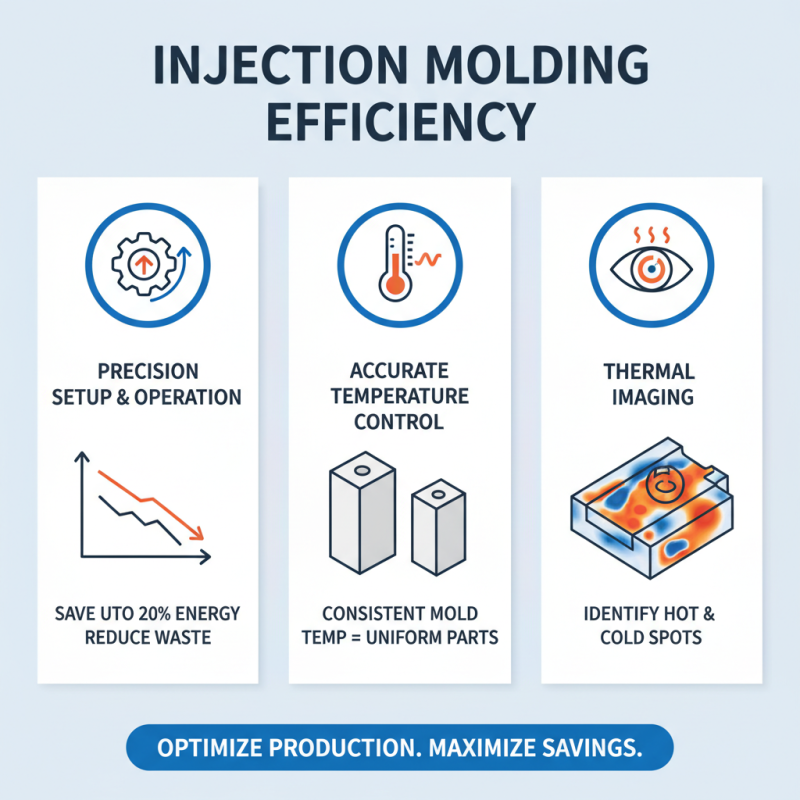

Large injection molding machines require precise setup and operation to achieve optimal efficiency. Data indicates that improperly calibrated machines can waste as much as 20% of energy. Accurate temperature control is crucial. For example, maintaining a consistent mold temperature leads to uniform part production. Use thermal imaging tools to identify hot and cold spots.

Proper material handling is equally important. Ensure that resin is dry before injection. Moisture content can affect the structural integrity of molded parts. Studies show that 80% of defects in molding can be traced back to material issues. Regular maintenance is key. Machines should be checked for wear and tear frequently. Neglecting this can lead to equipment failure and costly downtime.

Team training on machine operation can significantly reduce errors. Operators should understand the correlation between settings and final product quality. Inconsistent operation can lead to a lack of repeatability. Implementing a checklist for setup can help mitigate common mistakes. Reflect on past issues and use them as learning opportunities.

Common Challenges and Solutions in Large-Scale Injection Molding

Large-scale injection molding presents unique challenges in manufacturing. One common issue is inconsistent part quality. Variations can occur due to material flow, temperature control, or machine calibration. It's essential to monitor these factors closely. Regular maintenance of your machine can prevent many problems. If issues arise, analyze the part and identify the root cause.

Another challenge is the complexity of the molds used. Large molds are heavy and difficult to handle. This can lead to misalignment during production. Employing proper techniques for mold installation can minimize this risk. Training staff to understand the intricacies of these molds is also important.

When using large injection molding machines, keep the following tips in mind. Always perform a trial run with a test mold. This helps to ensure everything is functioning as expected. It's also vital to maintain a clear communication channel among your team. Regular updates about machine performance can foster quicker troubleshooting. Anticipating potential problems will lead to a smoother manufacturing process.

Best Practices for Maintenance and Troubleshooting of Molding Machines

Maintaining large injection molding machines is crucial for efficiency. Regular checks can prevent costly downtime. Operators should inspect hydraulic systems for leaks and wear. Lubrication of moving parts is essential. It's easy to overlook these details, but neglect can lead to bigger issues later.

Troubleshooting requires a keen eye. Monitor temperature fluctuations closely. Unusual sounds during operation often indicate problems. Small adjustments can make a significant difference. Operators should document any abnormalities. This practice helps identify patterns over time. Sometimes, the smallest changes yield the best results.

User training is vital. Many issues stem from operator error. Regular workshops can help reinforce best practices. Encourage team discussions about challenges faced. Sharing experiences can uncover hidden solutions. Remember, even seasoned operators can forget basics under pressure.

Essential Tips for Using Large Injection Molding Machines

| Maintenance Aspect | Best Practices | Troubleshooting Tips | Frequency |

|---|---|---|---|

| Hydraulic System | Check fluid levels and quality regularly. | If sluggish movement occurs, inspect hoses for leaks. | Monthly |

| Cooling System | Clean cooling channels and check for blockages. | If temperature fluctuation occurs, check coolant flow. | Bi-weekly |

| Mold Maintenance | Inspect and clean molds after every use. | If parts stick, use mold release agents. | After every production run |

| Electrical Systems | Check wiring and connections for wear. | If control panel fails, reset and inspect fuses. | Bi-monthly |

| Safety Checks | Ensure guards and sensors are operational. | If alarms sound, follow emergency protocols immediately. | Weekly |

Related Posts

-

Evaluating the Best Large Injection Molding Machines for Global Buyers in 2025 Industry Trends and Insights

-

How to Choose the Right Type of Injection Molding Machine for Your Business

-

Exploring the Diverse Types of Injection Molding Machines for Your Manufacturing Needs

-

Exploring the Advantages of Horizontal Injection Molding Machines in Modern Manufacturing

-

Top Benefits of Electric Injection Molding Machines for Your Manufacturing Needs

-

Top 10 Plastic Molding Machines for Efficient Manufacturing Solutions