Why You Should Consider Low Cost Injection Molding Machines for Your Business

In today's competitive market, businesses are constantly seeking ways to optimize production processes while keeping costs down. One often overlooked yet highly effective solution is the use of low cost injection molding machines. These machines offer an accessible entry point for small to medium-sized enterprises looking to manufacture high-quality plastic products without the significant financial burden typically associated with traditional injection molding equipment.

Low cost injection molding machines come equipped with various features that cater to the needs of modern manufacturing. They provide a high degree of efficiency, reliability, and flexibility, enabling businesses to adapt quickly to changing market demands. Additionally, investing in such machinery can significantly reduce overhead costs, allowing companies to allocate resources more effectively and ultimately enhance their profitability.

Considering the advantages of low cost injection molding machines, businesses can not only streamline their production processes but also improve product quality. By leveraging these machines, manufacturers can achieve shorter lead times and increased output, positioning themselves favorably amidst growing competition. Therefore, for businesses aiming to thrive in a cost-sensitive environment, adopting low cost injection molding machines could very well be a strategic move forward.

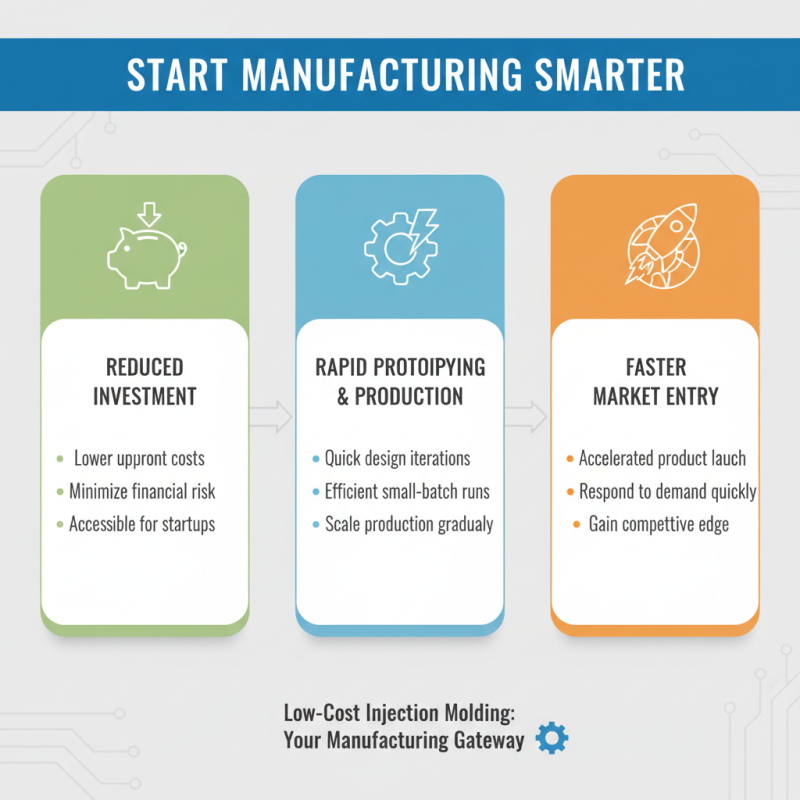

Benefits of Low-Cost Injection Molding Machines for Startups

Low-cost injection molding machines present an excellent opportunity for startups looking to enter the manufacturing sector without overwhelming initial investment. These machines not only reduce the financial burden but also enhance the ability to prototype and produce small to medium-sized batches efficiently. For new businesses, utilizing these cost-effective machines allows for faster product development and market entry, meaning they can respond to consumer demands promptly.

Tips for maximizing the benefits of low-cost injection molding machines include focusing on the design and materials used in your products. Simplifying designs can significantly reduce production time and costs. Additionally, selecting the right plastic materials that are readily available and well-suited for injection molding can help minimize waste and further decrease expenses.

Moreover, startups should take advantage of the scalability offered by low-cost injection molding machines. Starting small allows entrepreneurs to understand the nuances of their production processes and improve on them as they grow. Investing in training for staff on operating and maintaining these machines can also pay off in the long run, as it promotes efficiency and product quality from the very beginning of a business's journey.

Key Features to Look for in Affordable Injection Molding Equipment

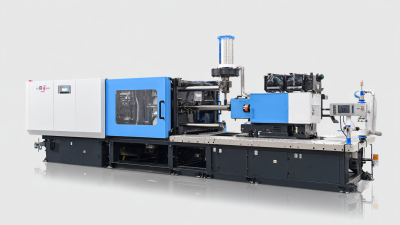

When considering low-cost injection molding machines, it’s essential to focus on key features that can enhance productivity and reduce costs. First and foremost, the machine's clamping force is crucial; it must be appropriately sized to accommodate the volume and weight of the materials being molded. A machine with adjustable clamping pressure can provide flexibility for different production runs, allowing businesses to mold a variety of products without the need for multiple machines.

Another important feature to examine is the control system of the injection molding machine. A user-friendly interface with programmable functions can streamline operations and minimize setup times. Look for machines equipped with advanced controls that offer real-time monitoring of parameters such as temperature and pressure, which can lead to consistent quality in production. Additionally, energy efficiency is a key consideration. Machines designed to consume less energy not only align with cost-saving measures but also contribute to environmentally friendly practices, which can be a selling point for modern businesses.

Comparative Analysis: Low-Cost vs. High-End Injection Molding Machines

When evaluating the merits of low-cost versus high-end injection molding machines, it is essential to consider the unique needs of your business and production environment. Low-cost injection molding machines typically offer a more accessible entry point for startups and small to medium-sized enterprises. They provide basic functionality and are ideal for prototyping or low-volume production runs. These machines often incur lower initial investments, which can be a significant advantage for businesses that need to conserve cash flow while still producing high-quality molded parts.

On the other hand, high-end injection molding machines come with advanced features that enhance precision, speed, and efficiency. They are designed for high-volume production and can handle complex mold designs, making them suitable for more demanding applications. While the upfront cost is substantially higher, the long-term benefits can justify the investment through reduced cycle times and increased output. Businesses in sectors that require continuous production and high-quality standards may find that high-end machines pay off over time through reliability and performance.

Ultimately, the choice between low-cost and high-end injection molding machines should be made based on factors like production volume, budget constraints, and the specific applications at hand. While low-cost options offer flexibility and lower financial risk, high-end machines promise efficiency and high-quality production, which can be indispensable for companies aiming to scale in competitive markets.

Comparison of Low-Cost vs. High-End Injection Molding Machines

Cost Savings: How Low-Cost Machines Impact Your Bottom Line

In today's highly competitive manufacturing landscape, cost-effective solutions have become paramount for businesses looking to optimize their operations and enhance profitability. Low-cost injection molding machines offer an excellent opportunity for businesses to significantly reduce production expenses. According to a report from MarketsandMarkets, the global injection molding machine market is expected to reach $14.54 billion by 2026. As more manufacturers turn towards affordable technology, the cost-effectiveness of these machines can lead to a noticeable improvement in the bottom line.

Investing in low-cost injection molding machines can have a substantial impact on operational costs. A study published by Grand View Research highlights that companies adopting cost-efficient machinery can reduce their production costs by up to 30%. This reduction enables businesses to allocate resources more efficiently, invest in innovation, and potentially increase their market share. Moreover, the initial lower investment allows smaller companies or start-ups to enter the market without incurring prohibitive expenses, thus encouraging entrepreneurship and fostering competition.

Moreover, the potential for high-volume production with low-cost machines means that businesses can meet growing demand without proportional increases in spending. As per data from the American Society of Mechanical Engineers, using automated low-cost machines can enhance production speed by over 50%. This not only allows businesses to maintain competitive pricing but also ensures quick turnaround times, which are critical in today's fast-paced market environment.

Case Studies: Successful Businesses Using Low-Cost Injection Molding

Low-cost injection molding machines have emerged as a game-changer for many startups and small businesses looking to optimize production without breaking the bank. A recent study by the National Association of Manufacturers indicates that more than 60% of new manufacturers are opting for low-cost machinery to remain competitive. These machines provide a cost-effective solution for producing high-quality parts, helping businesses keep production lean while maintaining profitability. For example, a small toy manufacturer was able to reduce its material costs by 30% by switching to a low-cost injection molding system, which not only improved their margins but also enabled them to lower retail prices, thereby increasing sales volume.

Case studies from various sectors illustrate the diverse applications and benefits of low-cost injection molding machines. In the automotive industry, a small component supplier found that utilizing these machines allowed them to produce complex parts with minimal labor costs and maximum efficiency. According to a report from the American Society of Mechanical Engineers, manufacturers using low-cost alternatives can expect to see a 25% improvement in turnaround time compared to traditional methods. This notable efficiency translates directly to enhanced customer satisfaction and faster delivery times, proving that investing in accessible technology can yield substantial returns for various businesses.

Why You Should Consider Low Cost Injection Molding Machines for Your Business - Case Studies: Successful Businesses Using Low-Cost Injection Molding

| Business Sector | Initial Investment (USD) | Production Volume (Units/Month) | Cost Savings (%) | Implementation Duration (Months) |

|---|---|---|---|---|

| Consumer Electronics | $15,000 | 10,000 | 25% | 2 |

| Automotive Parts | $20,000 | 5,000 | 30% | 3 |

| Healthcare Products | 12,000 | 15,000 | 20% | 1 |

| Household Goods | 10,000 | 20,000 | 18% | 2 |

| Toys | 8,000 | 25,000 | 22% | 1 |

Related Posts

-

Ultimate Injection Machine Comparison for Optimal Performance Selection

-

Addressing Common Challenges with Small Plastic Molding Machines in Production

-

How to Choose the Right Moulding Plastic Machine for Your Manufacturing Needs

-

Exploring the Diverse Types of Injection Molding Machines for Your Manufacturing Needs

-

Understanding the Different Types of Injection Molding Machines and Their Applications

-

Evaluating the Best Large Injection Molding Machines for Global Buyers in 2025 Industry Trends and Insights