How to Optimize Production Efficiency with Small Injection Molding Machines in Your Manufacturing Process

In the rapidly evolving landscape of manufacturing, optimizing production efficiency has become a paramount goal for many companies. One promising avenue is the integration of small injection molding machines in the production process. According to a report by Mordor Intelligence, the global injection molding machine market is projected to reach USD 29.8 billion by 2025, with a significant portion being driven by the demand for compact and efficient machinery.

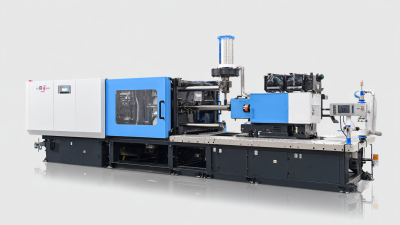

Small injection molding machines offer distinct advantages, including reduced energy consumption, lower material costs, and a smaller footprint, which make them an attractive choice for various applications. Furthermore, a study by Grand View Research indicates that the market for small injection molding machines is expected to grow as manufacturers increasingly adopt advanced technologies such as Industry 4.0, leading to enhanced automation and flexibility. By leveraging these machines, manufacturers can not only maximize output but also maintain high standards of quality and precision in their products.

Understanding the Advantages of Small Injection Molding Machines in Production

Small injection molding machines are becoming increasingly popular in various manufacturing sectors due to their numerous advantages. One significant benefit is their ability to optimize production efficiency in both small and large-scale operations. According to a report from the Plastics Industry Association, smaller machines can provide energy savings of up to 30% compared to larger counterparts, primarily due to their reduced cycle times and energy consumption during non-operational periods. This efficiency not only reduces operational costs but also minimizes the environmental impact of manufacturing.

Furthermore, small injection molding machines offer enhanced precision and flexibility, which is critical in today’s fast-paced market. A study by Mordor Intelligence indicates that the global small injection molding machine market is expected to grow at a CAGR of over 5% from 2021 to 2026. This growth reflects the increasing demand for rapid prototyping and customized production runs, which smaller machines excel at. Their compact size allows for easy integration into existing workflows, thereby streamlining the production process and reducing downtime. Ultimately, the strategic deployment of small injection molding machines can lead manufacturers toward greater innovation and competitiveness in their respective industries.

Identifying Key Factors for Optimal Machine Setup and Configuration

To achieve optimal production efficiency with small injection molding machines, it is crucial to identify and consider several key factors during the machine setup and configuration process. First and foremost, machine calibration plays a pivotal role. This involves adjusting parameters such as temperature, pressure, and cycle time to match the specific requirements of the material being used. Accurate calibration not only ensures the highest quality of molded parts but also minimizes waste and downtime, leading to increased productivity.

Another significant factor is the proper selection of molds and materials. Choosing the right combination not only enhances the efficiency of the production process but also affects the longevity of the molds themselves. Additionally, regular maintenance and inspection of the machines are vital in maintaining their performance and preventing unexpected breakdowns. By diligently addressing these aspects, manufacturers can significantly improve the overall efficiency of their production lines, making the most out of their investment in small injection molding machines.

How to Optimize Production Efficiency with Small Injection Molding Machines in Your Manufacturing Process

| Key Factor | Description | Optimal Value | Impact on Efficiency |

|---|---|---|---|

| Injection Pressure | The pressure at which the polymer is injected into the mold. | 650 - 1200 bar | High pressure ensures efficient filling and reduces cycle time. |

| Cooling Time | The time required to cool the molded part before ejection. | 10 - 20 seconds | Reduced cooling time increases machine throughput. |

| Mold Temperature | Temperature of the mold during the injection process. | 60 - 100 °C | Proper mold temperature optimizes material flow and part quality. |

| Cycle Time | Total time for one complete injection and cooling cycle. | 25 - 45 seconds | Shorter cycle times lead to increased production rates. |

| Screw Speed | Speed at which the screw rotates to plasticize the material. | 50 - 150 rpm | Optimal screw speed enhances material mixing and reduces cycle time. |

Implementing Best Practices for Material Selection and Management

In the realm of small injection molding, the selection and management of materials play a crucial role in optimizing production efficiency. Recent industry reports indicate that about 40% of production costs can be attributed to material selection, making it imperative for manufacturers to choose the right polymers that not only meet the application requirements but also enhance productivity. High-performance materials, such as polycarbonate and nylon, have shown to improve cycle times and overall output, while reducing scrap rates by as much as 20%, according to a study by the Plastics Industry Association.

Furthermore, efficient material management practices can significantly impact operational efficiency. Implementing just-in-time (JIT) inventory systems ensures that materials are available as needed, minimizing storage costs and waste. A report from the Manufacturing Institute highlights that companies adopting JIT practices experience a 15-30% reduction in material costs, alongside increased production agility. By evaluating factors such as material durability and compatibility with the injection molding process, manufacturers can foster a streamlined workflow that maximizes their small injection molding machines' capabilities, ultimately leading to a more efficient manufacturing operation.

Streamlining Workflow for Enhanced Operational Efficiency

Optimizing workflow with small injection molding machines is essential for enhancing operational efficiency in manufacturing processes. These compact machines allow for greater flexibility, enabling manufacturers to meet varying production demands without compromising on quality. By streamlining the workflow, companies can significantly reduce lead times and improve responsiveness to market changes. This flexibility is particularly valuable in environments where rapid prototyping and short-run production are required.

Implementing modular configurations and automation tools can further enhance efficiency. For example, integrating robotic systems with small injection molding machines can automate repetitive tasks, thus freeing up human resources for more complex operations. Additionally, adopting lean manufacturing principles helps in identifying and eliminating waste in the production process. This can include optimizing machine layouts, improving material handling, and ensuring adequate training for operators. Ultimately, these strategies not only improve production flow but also contribute to significant cost savings and higher overall productivity.

Production Efficiency of Small Injection Molding Machines

This bar chart illustrates the production efficiency of small injection molding machines across different parameters, including Cycle Time, Machine Utilization, and Quality Rate.

Utilizing Maintenance Strategies to Maximize Machine Longevity and Performance

Optimizing production efficiency with small injection molding machines not only hinges on the machines themselves but significantly relies on effective maintenance strategies. Incorporating preventative and predictive maintenance practices can lead to substantial improvements in machine longevity and operational performance. By integrating advanced technologies such as sensors and IoT data, manufacturers can transition from reactive to proactive maintenance approaches. This shift allows for timely interventions that minimize unplanned downtimes and enhance the overall reliability of machinery.

Optimizing production efficiency with small injection molding machines not only hinges on the machines themselves but significantly relies on effective maintenance strategies. Incorporating preventative and predictive maintenance practices can lead to substantial improvements in machine longevity and operational performance. By integrating advanced technologies such as sensors and IoT data, manufacturers can transition from reactive to proactive maintenance approaches. This shift allows for timely interventions that minimize unplanned downtimes and enhance the overall reliability of machinery.

Moreover, the systematic management of machine maintenance ensures that every component functions at its best, ultimately resulting in increased throughput and reduced operational costs. For instance, analyzing historical performance data can help predict potential failures, which can then be addressed before they disrupt production. As industries move towards smarter, data-driven solutions, the importance of these maintenance strategies cannot be overstated. This proactive stance aligns with current trends in various sectors, emphasizing the need for sustainable and efficient manufacturing practices that can withstand the challenges of modern production demands.

Related Posts

-

7 Best Small Plastic Injection Machines for Efficient Production in 2023

-

How to Choose the Best Home Plastic Injection Molding Machine for Your DIY Projects

-

Rise of Plastic Injection Machine Technology at the 138th China Import and Export Fair 2025 Shaping Industry Trends

-

Understanding the Different Types of Injection Molding Machines and Their Applications

-

Exploring Innovative Alternatives to Plastic Injection Machines for Modern Manufacturing

-

Comparing Efficiency and Cost: Mini Plastic Injection Molding Machines Vs. Traditional Methods