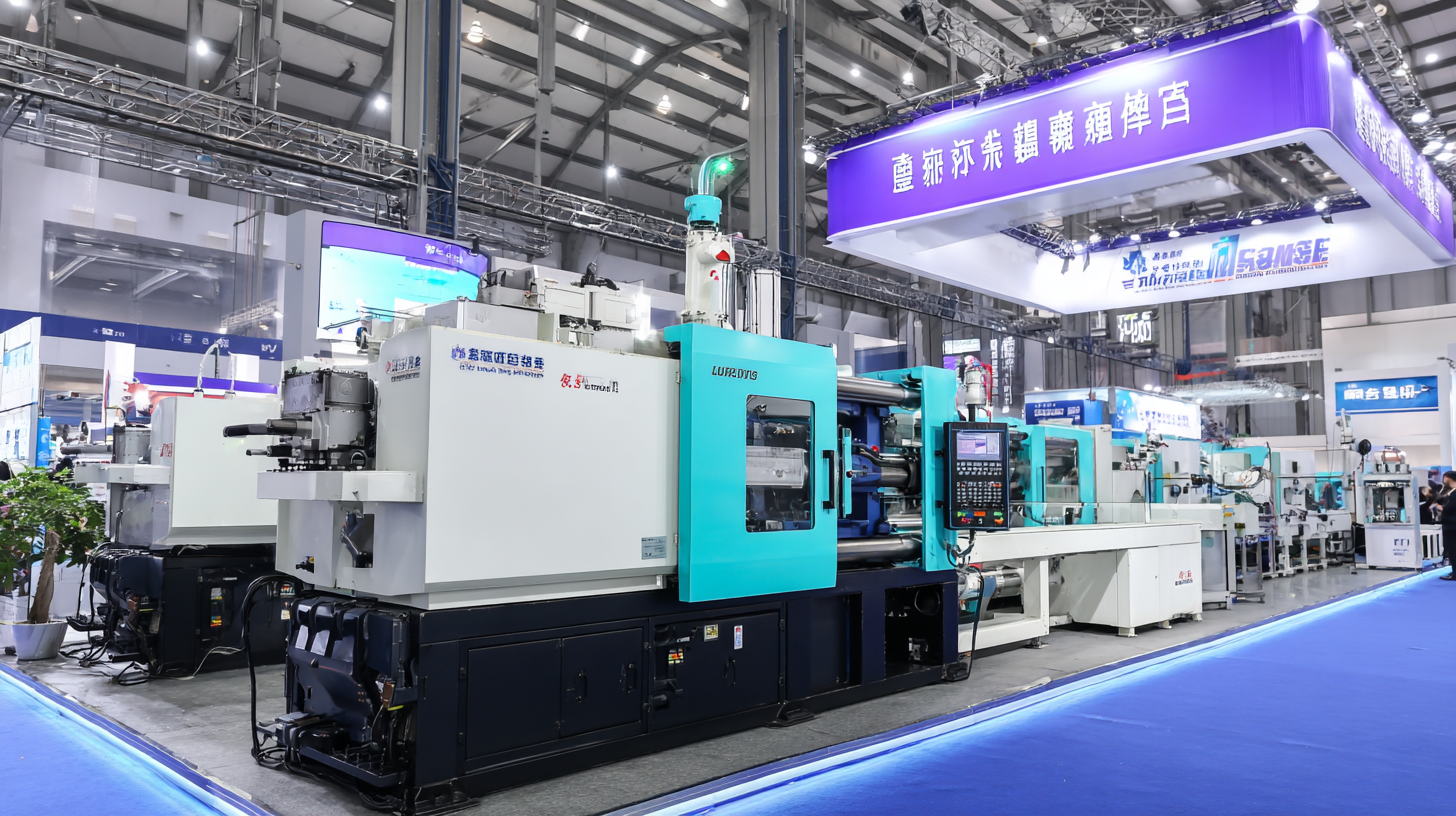

Rise of Plastic Injection Machine Technology at the 138th China Import and Export Fair 2025 Shaping Industry Trends

The 138th China Import and Export Fair in 2025 is set to showcase a significant evolution in manufacturing technology, particularly with the rise of plastic injection machine technology. As industries increasingly prioritize efficiency and sustainability, the global plastic injection molding machine market is projected to grow at a compound annual growth rate (CAGR) of over $9 billion through 2027. This growth is attributed to the expanding applications of plastic products across diverse sectors, including automotive, consumer goods, and medical devices. The fair will serve as a pivotal platform for industry leaders to unveil innovations that enhance production capabilities, reduce waste, and meet stringent environmental regulations.

The 138th China Import and Export Fair in 2025 is set to showcase a significant evolution in manufacturing technology, particularly with the rise of plastic injection machine technology. As industries increasingly prioritize efficiency and sustainability, the global plastic injection molding machine market is projected to grow at a compound annual growth rate (CAGR) of over $9 billion through 2027. This growth is attributed to the expanding applications of plastic products across diverse sectors, including automotive, consumer goods, and medical devices. The fair will serve as a pivotal platform for industry leaders to unveil innovations that enhance production capabilities, reduce waste, and meet stringent environmental regulations.

With advancements in automation and the integration of smart technologies, the plastic injection machine sector is poised to play a critical role in shaping the future of manufacturing, making the 138th Fair a must-attend event for stakeholders eager to stay ahead in this dynamic landscape.

The Evolution of Plastic Injection Molding Technology Featured at the 138th Canton Fair

The 138th Canton Fair highlights a significant evolution in plastic injection molding technology, emphasizing the industry's shift towards more innovative and efficient practices. With advancements in computer-aided design (CAD) and the integration of multistrategy differential evolution algorithms, manufacturers are now able to optimize the injection molding process. This evolution not only enhances the precision of tooling but also improves the overall effectiveness of the manufacturing process, showcasing a commitment to quality and innovation in plastic production.

Moreover, industry leaders are stepping up to redefine their roles in the market. Custom injectors are no longer limited to traditional practices; they are becoming champions of super-precise tooling and advanced metrology techniques. The focus has shifted to adapting to customer needs through evolution and sustainability efforts. By collaborating with cutting-edge technology and embracing future-oriented cultures, companies are positioned to shape industry trends and set new standards at this important trade fair.

Key Market Insights: Projected Growth and Demand for Injection Molding Machines by 2025

The 138th China Import and Export Fair in 2025 is expected to highlight significant advancements in plastic injection machine technology, reflecting the growing demands of various industries. With the surge in automation and sustainable manufacturing processes, the market for injection molding machines is projected to experience robust growth. The rise in consumer goods production, automotive parts, and packaging solutions underscores the increasing reliance on efficient and innovative molding technologies.

Market insights indicate that the demand for injection molding machines is anticipated to expand, driven by factors such as technological advancements, increased production capacities, and a shift towards eco-friendly materials. Manufacturers are investing heavily in research and development to produce energy-efficient machines that minimize waste and enhance productivity. As industries strive to meet evolving consumer expectations while adhering to stringent environmental regulations, the development of advanced injection molding solutions will play a crucial role in shaping market dynamics through 2025 and beyond.

Innovations in Electric vs. Hydraulic Plastic Injection Machines: Efficiency Metrics and Industry Impact

The 138th China Import and Export Fair in 2025 is set to highlight significant advancements in plastic injection machine technology, focusing particularly on the innovations in electric versus hydraulic models. As the market transitions, electric injection molding machines are gaining traction due to their energy efficiency and precision, which align with increasing demands for sustainability in manufacturing processes. This shift not only reduces production costs but also lessens the environmental impact, presenting a compelling case for manufacturers to invest in cutting-edge machinery.

On the other hand, hydraulic machines, traditionally favored for their robust performance in high-volume production, are also experiencing innovations aimed at improving efficiency metrics. These advancements include enhanced control systems and energy-saving features, bridging the gap between performance and sustainability. As the global injection molding machine market is expected to grow significantly over the next decade, driven by increasing demand in various sectors, the competition between electric and hydraulic machines will define industry trends and set the stage for future manufacturing practices. The insights gleaned from this fair will undoubtedly influence the technological landscape and operational strategies across the industry.

Efficiency Comparison of Electric vs. Hydraulic Plastic Injection Machines

This bar chart illustrates the comparative energy efficiency of electric and hydraulic plastic injection machines, highlighting the increasing trend towards electric machines owing to their superior efficiency metrics.

Sustainability in Plastic Injection Technology: Trends Towards Eco-friendly Manufacturing Practices

The push towards sustainability in plastic injection technology is transforming manufacturing practices, particularly highlighted during the 138th China Import and Export Fair in 2025. As the global market for plastic injection molding continues to expand, reaching an estimated value of $235.7 billion, there is a growing emphasis on eco-friendly solutions. Innovations in biodegradable plastics have become increasingly significant, presenting opportunities to reduce plastic waste and environmental impact.

One promising avenue is the exploration of sustainable feedstocks, such as Azolla, for bioplastic production. These initiatives not only align with the circular economy model but also aim to mitigate the carbon footprint associated with traditional plastics. Additionally, advancements in 3D printing technologies are facilitating the upcycling of plastic waste into innovative polymer blends. By integrating recycled materials and biomass into the production process, the industry is making strides towards a more sustainable and responsible future, reflecting a commitment to environmental stewardship amidst rising consumption trends.

Impact of Automation and Smart Technology on Injection Molding Industry Dynamics at the Fair

The 138th China Import and Export Fair in 2025 is set to showcase significant advancements in plastic injection machine technology, particularly through the lens of automation and smart technology. Industry reports indicate that the global injection molding market is projected to reach USD 335.22 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.5% from 2021. This growth is largely driven by the adoption of automated systems that enhance production efficiency and reduce operational costs, allowing manufacturers to meet the rising demand for customized plastic products.

Smart technology integration, such as IoT and AI, is also reshaping the dynamics of the injection molding industry. By leveraging real-time data analytics, companies can optimize mold designs, monitor machine performance, and predict maintenance needs, thereby significantly minimizing downtime. According to a recent study by MarketsandMarkets, the smart manufacturing market, which includes automation technologies, is expected to grow from USD 199.78 billion in 2020 to USD 384.85 billion by 2025, marking a promising trend for industries heavily reliant on injection molding processes. The advancements showcased at the Fair will undoubtedly highlight the transformative potential of these technologies, paving the way for a more efficient and sustainable manufacturing future.

Related Posts

-

Exploring Innovative Alternatives to Plastic Injection Machines for Modern Manufacturing

-

How to Enhance Production Efficiency with Plastic Injection Machines for Optimal ROI

-

Global Quality Revolution How Chinese Moulding Plastic Machines Capture International Markets

-

Addressing Common Challenges with Small Plastic Molding Machines in Production

-

Exploring the Comparative Benefits of Different Injection Molding Machine Types

-

How to Choose the Best Home Plastic Injection Molding Machine for Your DIY Projects