Top Small Plastic Injection Molding Machine Options for Your Business?

In today's dynamic manufacturing landscape, small plastic injection molding machines are gaining traction. These machines are crucial for businesses looking to streamline production and minimize costs. According to industry expert Dr. Emily Chang, "The efficiency of small plastic injection molding machines can revolutionize small-scale manufacturing." Her words highlight the importance of these machines in enhancing productivity.

Small plastic injection molding machines are versatile tools. They can produce a wide array of products, from intricate components to everyday items. The right machine can significantly impact production quality and speed. However, choosing the right machine requires careful consideration. Factors like size, output capacity, and material compatibility must all be evaluated.

While many manufacturers offer great options, some may not meet specific needs. Reflecting on choices, a business must weigh cost versus capability. Investing in the wrong machine can hinder growth. Therefore, it's vital to research and understand the specific requirements before making a decision.

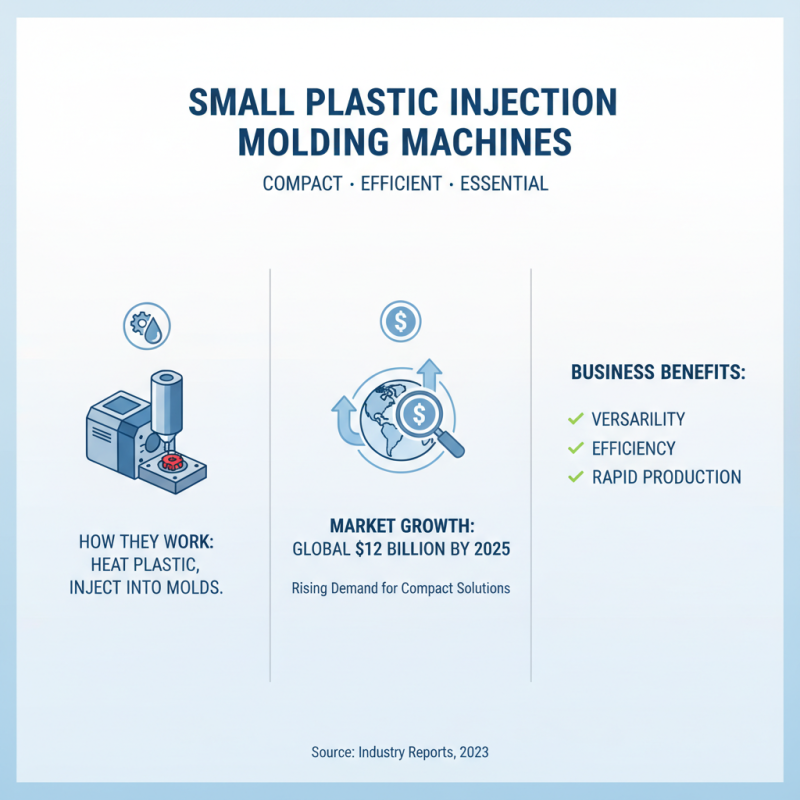

Overview of Small Plastic Injection Molding Machines

Small plastic injection molding machines are crucial for many businesses today. They offer versatility and efficiency. These machines work by heating plastic and injecting it into molds. According to industry reports, the global market for injection molding machines is projected to reach $12 billion by 2025. This growth underscores the rising demand for compact and efficient production solutions.

These machines are ideal for small to medium production runs. They typically have a clamping force ranging from 20 to 100 tons. This range accommodates various small parts manufacturing, from automotive components to consumer goods. Many users report challenges in achieving consistent quality. Factors like material type and temperature control can impact results. Additionally, businesses may struggle with the initial setup costs, which can be significant for smaller operations.

The ease of use is a key feature of these machines. Many come equipped with user-friendly interfaces. However, operators often require proper training to maximize their efficiency. Inadequate training can lead to production downtime or increased waste. Regular maintenance is also essential, yet many businesses overlook this aspect, impacting overall productivity. These considerations highlight the importance of investing in training and upkeep for long-term success.

Key Factors to Consider When Choosing a Machine

Choosing the right small plastic injection molding machine is critical for your business. Start by considering the machine’s size and capacity. It must match your production needs. Small machines are great for low-volume projects, but they may struggle with larger runs. Assess your current and future production requirements carefully.

Next, look at the machine's ease of use. A complicated machine may slow down production. Operators should feel comfortable running it. User-friendly controls can make maintenance simpler. Also, consider energy efficiency. Machines that consume less power can save money in the long run.

Don’t forget to evaluate the after-sales support. In case of a breakdown, swift support is vital. Delays in repairs can lead to downtime and lost revenue. It's important to find a balance between cost and reliability. Sometimes, a lower-priced machine may not be the best investment. Each choice comes with trade-offs that require careful thought.

Top Small Plastic Injection Molding Machine Options for Your Business

This bar chart illustrates various small plastic injection molding machines categorized by their clamping force capability. Each machine option is represented by its respective clamping force in tons, aiding in the decision-making process for businesses seeking suitable machines.

Top Brands and Models in Small Plastic Injection Molding

In the realm of small plastic injection molding, various brands and models stand out. The right machine can enhance production efficiency and reduce costs. According to recent industry reports, the demand for small-scale injection molding machines has surged by approximately 12% annually. This growth is fueled by the rise of small manufacturers seeking to create custom plastic parts.

When choosing a small injection molding machine, factors such as clamping force and shot size are crucial. Many models cater to different production needs. For instance, some machines offer a clamping force range of 30 to 50 tons. This versatility allows businesses to produce a variety of components. Yet, not every model shines in every application. Some users report issues with precision when scaling up production.

Additionally, energy efficiency is becoming a significant concern. Reports indicate that energy-efficient machines can lower operational costs by up to 25%. However, many companies still rely on older models that consume more energy. This oversight can set businesses back financially. Vacuum pressure and injection speed also play pivotal roles in determining the overall output quality. Finding the right balance may require trial and error, but the rewards can be substantial.

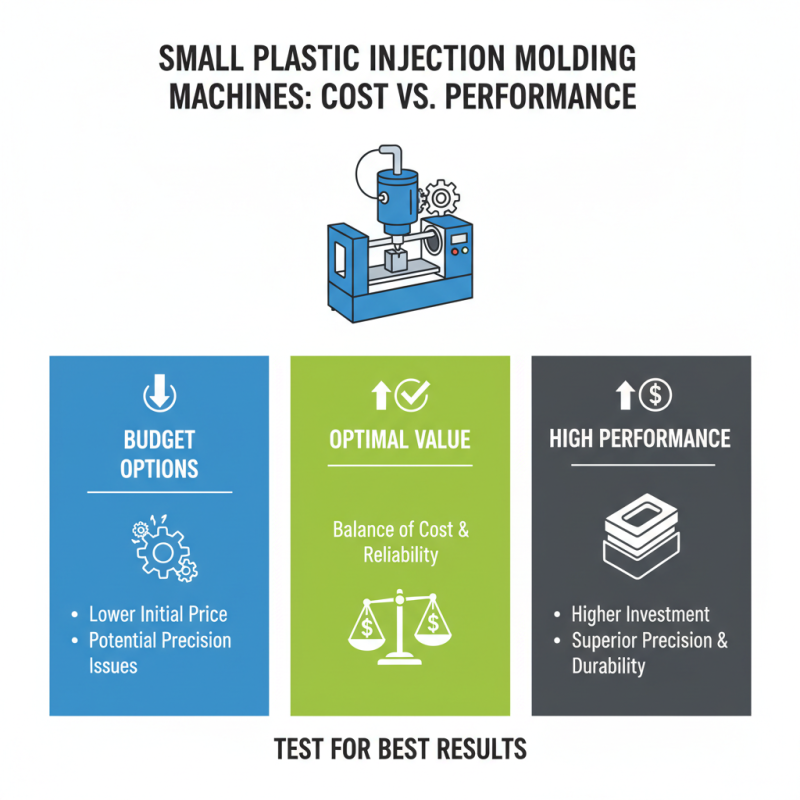

Comparative Analysis of Cost and Performance

When considering small plastic injection molding machines, cost and performance are key factors. Many options vary widely in price. Budget constraints often dictate choices. However, the cheapest machines may not always deliver the best results. Testing multiple models can be beneficial. Sometimes, cheaper machines struggle with precision.

Performance is equally important. Some machines provide high production rates but lack reliability. Others may excel in quality but at a higher cost. Finding a balance is crucial. Users should analyze specific needs. Will they prioritize speed or quality? Diving deeper into reviews can reveal insights. Often, real-life performance differs from specifications.

Additionally, the learning curve for operating these machines should not be ignored. Some may require extra training, leading to hidden costs. Others can be more user-friendly, thus saving time. Evaluating user experiences might highlight these nuances. Investing in a versatile machine can yield better long-term value. In essence, a thorough comparative analysis is vital for solid decision-making.

Maintenance Tips for Small Plastic Injection Molding Machines

Small plastic injection molding machines are essential for many businesses. Regular maintenance ensures their efficiency and longevity. Start by cleaning the machine regularly. Dust and debris can hinder performance. Check for any wear and tear on moving parts. Notice any unusual noises? They may indicate a problem.

Lubrication is vital. All moving parts should be regularly greased. But, over-lubricating can cause issues too. Balance is key here. You might forget about the heating elements in your machine. Ensure they are functioning correctly to maintain consistent production quality.

Monitor the hydraulic system as well. Low fluid levels can cause malfunctions. Replace worn seals and hoses promptly. Failing to address these issues can lead to costly downtime. Lastly, consider keeping a maintenance log. Documenting your upkeep can help spot patterns and prevent future problems. It’s a small habit that can have big rewards.

Top Small Plastic Injection Molding Machine Options for Your Business - Maintenance Tips for Small Plastic Injection Molding Machines

| Machine Type | Clamping Force (tons) | Injection Capacity (grams) | Energy Efficiency (%) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Vertical Injection Machine | 10 | 50 | 90 | 6 |

| Hybrid Injection Machine | 15 | 75 | 85 | 12 |

| Standard Electric Injection Machine | 25 | 100 | 80 | 8 |

| Micro Injection Molding Machine | 5 | 10 | 95 | 4 |

| Compact Injection Machine | 20 | 60 | 88 | 10 |

Related Posts

-

7 Best Small Plastic Injection Machines for Efficient Production in 2023

-

How to Optimize Production Efficiency with Small Injection Molding Machines in Your Manufacturing Process

-

Top 5 Mini Plastic Injection Molding Machines You Should Consider

-

Comparing Efficiency and Cost: Mini Plastic Injection Molding Machines Vs. Traditional Methods

-

2025 Top Automatic Molding Machine Innovations for Efficient Production

-

Why Electric Injection Molding Machines Are Revolutionizing Manufacturing Efficiency