Top 10 Plastic Molding Machines for Efficient Manufacturing Solutions

In the rapidly evolving landscape of manufacturing, the significance of plastic molding machines cannot be understated. These machines play a vital role in transforming raw materials into functional and innovative products that serve various industries, from automotive to consumer goods. As industry expert Dr. Emily Tran once noted, "The efficiency and precision of a modern plastic molding machine can drastically enhance production capabilities, leading to significant cost savings and improved product quality."

The advancements in technology surrounding plastic molding machines are a testament to the ongoing quest for efficiency and sustainability in manufacturing processes. With a plethora of models available, choosing the right plastic molding machine aligns closely with the specific needs of production lines. From energy-efficient designs to multifunctional capabilities, the top contenders in the market offer solutions that not only cater to current demands but also anticipate future trends in manufacturing.

As we delve into the top 10 plastic molding machines celebrated for their innovation and performance, we will explore the features that set them apart in the competitive landscape, ensuring manufacturers can make informed decisions to boost their operational efficiency and product output.

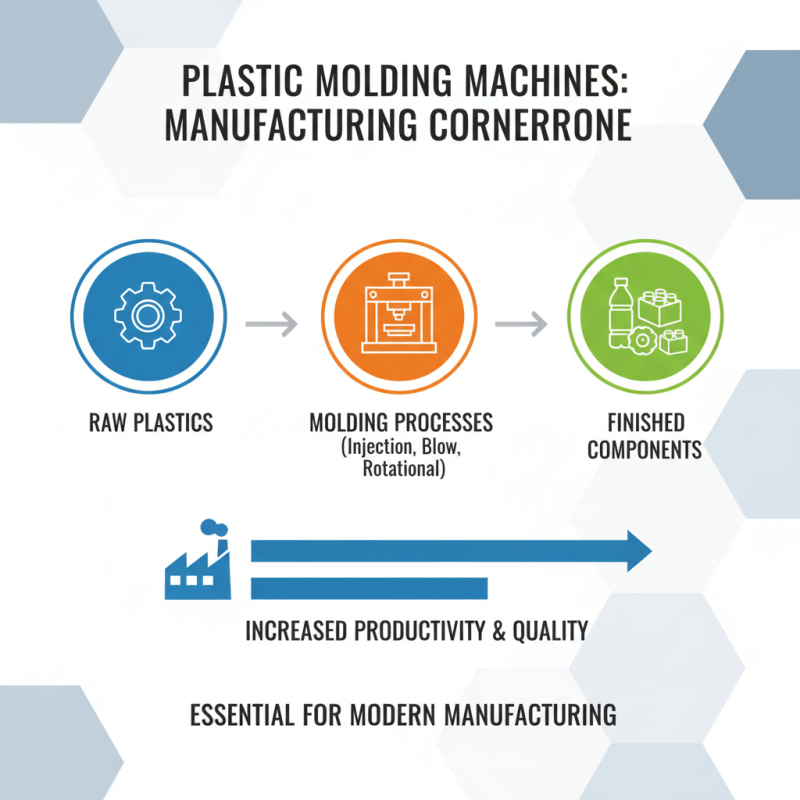

Overview of Plastic Molding Machines in Manufacturing

Plastic molding machines play a crucial role in the manufacturing sector, particularly in the production of plastic components used in various industries. These machines are engineered to convert plastic materials into a variety of shapes and sizes through processes such as injection molding, blow molding, and rotational molding. The efficiency of plastic molding machines directly impacts the overall productivity and quality of manufactured goods, making them a cornerstone of modern manufacturing.

In today’s fast-paced industry, choosing the right plastic molding machine can significantly enhance operational efficiency. Advances in technology have led to the development of machines that not only improve precision and speed but also reduce energy consumption and waste. Manufacturers are increasingly looking for solutions that offer automation and integration capabilities, streamlining workflows and minimizing downtime. An overview of the latest innovations in plastic molding machines reveals trends towards enhanced user interfaces and smart features that assist operators in managing processes effectively, thereby ensuring consistency and reliability in production outcomes.

Key Features and Specifications for Efficient Operation

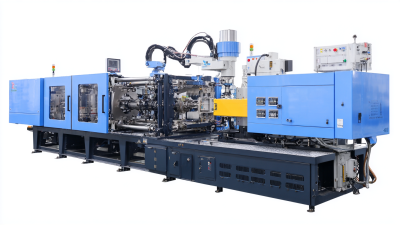

When evaluating plastic molding machines for efficient manufacturing solutions, several key features and specifications must be considered to ensure optimal operation. Firstly, the clamping force plays a crucial role, as it determines the ability of the machine to maintain mold integrity under high pressure.

A robust clamping unit paired with a precision hydraulic system enhances the machine's performance, allowing for quick and secure mold changes, which significantly reduces downtime. Additionally, the incorporation of advanced control systems facilitates real-time monitoring and adjustment, boosting operational efficiency.

Another essential aspect is the machine's energy consumption. Modern plastic molding machines are increasingly designed with energy efficiency in mind, utilizing servo motors that adjust power usage according to demand. This not only lowers operational costs but also supports sustainable manufacturing practices. Furthermore, a versatile temperature control system ensures that materials are processed at optimal conditions, minimizing defects and enhancing product quality. Overall, these key features contribute to the effectiveness of plastic molding machines in delivering reliable and high-quality outputs in various manufacturing settings.

Top 10 Plastic Molding Machines: Rankings and Reviews

The landscape of plastic molding machines is continually evolving, driven by technological advancements and the need for increased efficiency in manufacturing. Recent industry reports indicate that the global plastic injection molding machine market is projected to reach USD 17.5 billion by 2026, growing at a CAGR of 4.3% from 2021. This growth is propelled by industries such as automotive, consumer goods, and healthcare, where high precision and rapid production rates are paramount.

In assessing the top plastic molding machines, factors such as energy efficiency, automation capabilities, and material versatility are critical. The integration of Industry 4.0 technologies into molding processes has significantly enhanced operational efficiency. For example, machines equipped with IoT connectivity can monitor performance in real-time, allowing for predictive maintenance and reducing downtime. Advanced servo motors and hydraulic controls have also contributed to reduced energy consumption, with reports suggesting that modern machines can offer energy savings of up to 70% compared to older models.

Moreover, market research highlights a growing trend towards the adoption of eco-friendly materials and production methods, aligning with global sustainability goals. The demand for machines capable of processing biodegradable plastics is on the rise as manufacturers seek to minimize their environmental footprint. As the industry progresses, companies are increasingly prioritizing solutions that not only meet production demands but also align with sustainable practices.

Top 10 Plastic Molding Machines for Efficient Manufacturing Solutions

| Machine Type | Clamping Force (tons) | Injection Weight (g) | Cycle Time (seconds) | Energy Efficiency Rating |

|---|---|---|---|---|

| Electric Molding Machine | 150 | 500 | 25 | A+ |

| Hydraulic Molding Machine | 200 | 600 | 30 | B |

| Hybrid Molding Machine | 180 | 550 | 27 | A |

| Vertical Molding Machine | 120 | 400 | 22 | B+ |

| High-Speed Molding Machine | 160 | 520 | 20 | A++ |

| Multi-Cavity Molding Machine | 190 | 580 | 28 | A |

| Tabletop Molding Machine | 100 | 300 | 35 | B |

| Cold Runner Molding Machine | 170 | 540 | 29 | A |

| Hot Runner Molding Machine | 210 | 620 | 23 | A++ |

| Bi-Injection Molding Machine | 160 | 500 | 25 | A+ |

Comparative Analysis of Performance and Cost-Effectiveness

In the realm of manufacturing, the efficiency and effectiveness of plastic molding machines play a critical role in the production process. Evaluating performance metrics such as cycle time, energy consumption, and precision provides valuable insights into how these machines can optimize production lines.

For instance, machines that offer rapid cycle times can significantly enhance throughput, while those that minimize energy usage not only reduce operational costs but also contribute to sustainability efforts. Additionally, precision engineering ensures that products meet tight tolerances, further improving overall production quality.

When considering cost-effectiveness, it is vital to analyze both initial investments and long-term operational expenses. While some machines may have a higher upfront cost, their durability and lower maintenance requirements can lead to increased savings over time.

Advanced technology features can also provide a competitive edge, allowing manufacturers to adapt to changing market demands without substantial additional costs. This comparative analysis enables businesses to make informed decisions, balancing the benefits of performance enhancements with the realities of economic constraints in manufacturing environments.

Future Trends in Plastic Molding Technology and Innovation

The landscape of plastic molding technology is evolving rapidly, driven by innovations that enhance efficiency and sustainability in manufacturing processes. According to a recent report by Grand View Research, the global plastic injection molding market is expected to reach USD 457.26 billion by 2028, growing at a CAGR of 5.1% from 2021. This growth is largely fueled by advancements in machinery and materials, which are becoming increasingly important as manufacturers seek to minimize waste and improve energy efficiency.

Recent trends in plastic molding technology emphasize automation and smart manufacturing. Integration of IoT devices facilitates real-time monitoring and predictive maintenance, reducing downtime and optimizing production output. Furthermore, the adoption of eco-friendly materials and bioplastics is gaining momentum, spurred by regulations aimed at reducing environmental impact. According to a study by ResearchAndMarkets, the bioplastics market alone is projected to grow by 19.5% annually through 2027, highlighting a significant shift towards sustainable solutions in the industry. As manufacturers continue to embrace these innovations, the future of plastic molding will likely be characterized by greater efficiency and reduced ecological footprints.

Top 10 Plastic Molding Machines - Efficiency Ratings

Related Posts

-

Maximizing Production Efficiency with Advanced Plastic Molding Machines

-

How to Choose the Right Moulding Plastic Machine for Your Manufacturing Needs

-

Top 10 Best Moulding Plastic Machines for Efficient Production

-

Global Quality Revolution How Chinese Moulding Plastic Machines Capture International Markets

-

Ultimate Injection Machine Comparison for Optimal Performance Selection

-

Understanding the Impact of Injection Molding Machines on Modern Manufacturing Efficiency